Note: Before you start this article take note that the LED lighting code and word recognition should still work but twitter have made it so you can’t access tweets this way anymore. You have to sign up to be a developer and insert authentication code. I am trying to currently repair this but twitter aren’t making it easy 😛

For future projects and general usefulness I have decided to try to learn a new programming language. I have decided to try python for two good reasons, because it is a good language to program projects with the Raspberry Pi and because a large chunk of my course next year is programming simulations in python.

For my first program I’m going to do a twitter feed controlled LED, I also plan to incorporate twitter into a later project so this is a good starting point.

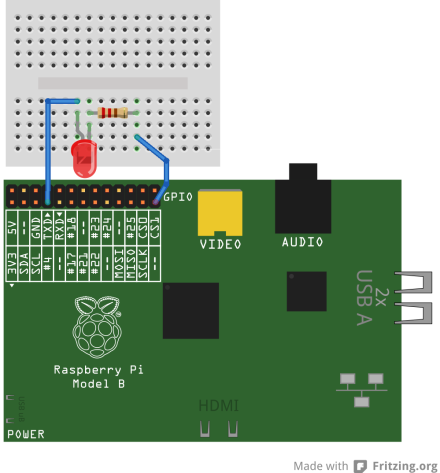

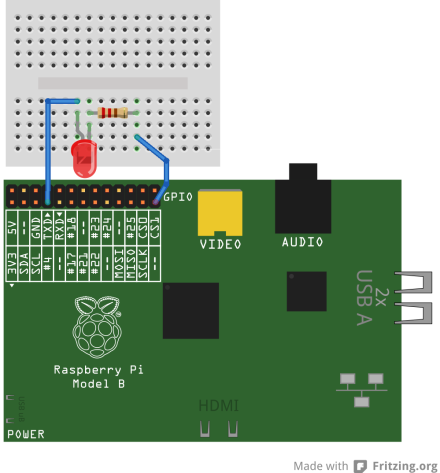

Ingredients list: A Raspberry Pi, an LED, a 220 Ohm resistor, Internet access and a Twitter account.

First take an LED and a 220 Ohm resistor and connect the resistor to the cathode of the LED. Then connect the anode of the LED to pin 7 of the GPIO pins on the Raspberry Pi and the resistor to pin 25 using two female to female jumper wires. A GPIO pin layout diagram can be found here. Once you are sure this is done correctly, a mistake could damage the Pi, boot up your Raspberry Pi ( I am using Raspbian Wheezy). This is all the hardware setup.

Now to install the appropriate libraries type this into the command line:

wget https://raw.github.com/Rob-Bishop/RaspberryPiRecipes/master/InstallTweetLEDLibraries.sh

Now run the installer by typing sudo: sh InstallTweetLEDLibraries.sh

Okay you know have the appropriate library the next step is to create the file. I’m using nano, to make he file type this command:

nano TweetLED.py

In the editor you just opened type the following code, quick tip press CTRL X to save and exit the editor. Note, I am going to put ; at the end of each line to make the program clearer do not put these into your program.

import urllib ;

import simplejson ;

import time ;

import RPi.GPIO as GPIO ;

;

GPIO.cleanup() ;

GPIO.setmode(GPIO.BOARD) ;

GPIO.setup(7,GPIO.OUT) ;

;

def latest_tweet(twitter_handle): ;

twitter_results = urllib.urlopen(‘http://’+’search.twitter.com/search.json?q=’+twitter_handle) ;

result_list = simplejson.loads(twitter_results.read()) ;

return result_list[‘results’][0][‘text’] ;

;

count = 1 ;

;

while count > 0: ;

tweet=latest_tweet(‘@JamesLeftley’) ;

;

if ‘on’ in tweet: ;

print tweet,’ – LED ON’,’\n’ ;

GPIO.output(7,GPIO.HIGH) ;

;

if ‘off’ in tweet: ;

print tweet,’ – LED OFF’,’\n’ ;

GPIO.output(7,GPIO.LOW) ;

;

if ‘stop’ in tweet: ;

print tweet,’ – Stopped’,’\n’ ;

GPIO.output(7,GPIO.LOW) ;

count = 0 ;

;

time.sleep(2) ;

Now save and exit using CTRL X and you should be taken back to the command line. To run the program type:

sudo python TweetLED.py

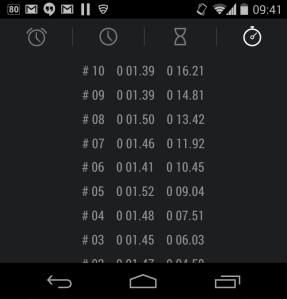

To stop the program tweet stop, to turn the LED on tweet on and to turn the LED off tweet off. The tweets can say anything as long as they include the twitter handle, in this case @JamesLeftley, and the command. All the commands are case sensitive.

To personalise the program change the twitter handle, add more outputs and change the commands.

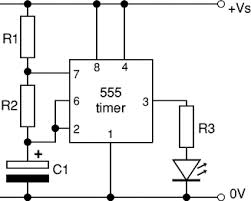

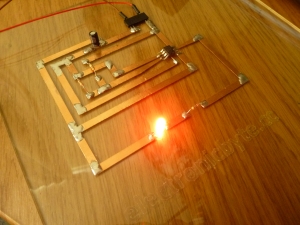

Through my time learning about electronics, I have come to realise that the 555 timer circuit, astable or monostable, is one of the first circuits anyone should make.

Through my time learning about electronics, I have come to realise that the 555 timer circuit, astable or monostable, is one of the first circuits anyone should make.